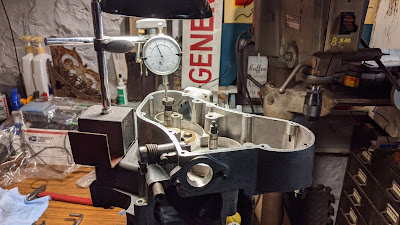

Had another go at shimming up the spare MSS engine last night. Without shims under the race, I was getting an indication of about 0.006".

After a bit of quadruple checking it; seems that the next move would be to add one of the shims that came out of it and see what the results will be . Some of the reasons for this whole exercise, apart from the self educational standpoint; this engine had been sitting in a basement for 26 years, the cases had a cork gasket between the halves. As far as I've been told, Velocette didn't seal the case halves with gaskets.

Before getting on with heating up the case I needed to modify the block of aluminum I had cut to fit on the race. It was meant to have a weight on top to hold the race seated, keeping it pushed into the case while it cooled. Rather than a weight, I drilled a hole so it could be bolted up to keep pressure; insuring the race was seated in the case and on the shim. From there, pulled out the burner assembly, set the case half on it and gave it a go.

While waiting for the the whole lot to cool and settle (I'll check it tomorrow) I took some time to goof with making a few pins that might help with the installation of the oil pump, when that time comes.

Nothing special about them, a section of 3/16" rod threaded on one end and the other a slot cut in case they prove to be difficult to remove after a pump has been installed. whether this idea will work, no idea. My reasoning was to keep the twisting of the pump to a minimum during installation. Worst case, the pump body could jam on the pins. I did a check in the reverse direction to test the base fitment on the pins with the base alignment to the case.

No comments:

Post a Comment